Application of air purification equipment in the biopharmaceutical industry

时间:2021/7/5 9:52:59

For clean rooms of various cleanliness levels, three-stage filtration of primary efficiency, medium efficiency and high efficiency should be adopted. According to the collected information of relevant pharmaceutical companies, the basic method is to install primary and medium-efficiency filters in the air-conditioning box, and use high-efficiency filters at the end of each clean room. If possible, install primary and medium-efficiency filters in the air-conditioning box. High-efficiency, high-efficiency filter, with high-efficiency filter at the end.

For B/C/D grade clean areas, the top-feed and lower-side return air should be preferentially adopted, and the corresponding airflow should adopt a non-unidirectional flow pattern. From the point of view of the principle of air purification, the clean air volume required by this method is lower than other forms of air return (such as side delivery and lower side return, top delivery and top return, etc.). High-efficiency air supply outlets are usually used as end clean equipment in clean rooms with these cleanliness levels (as shown in Figure 1). The air supply port includes a static pressure box and a high-efficiency filter. The high-efficiency filter usually selects H13 or H14 efficiency, which has the advantages of simple structure, low cost, and convenient installation.

Application of air purification equipment in the biopharmaceutical industry

For the clean air flow in the Class A clean area, a unidirectional flow pattern is usually adopted. According to the cleanliness, wind speed, noise, vibration, illuminance, air flow pattern, PAO detection, etc. required by the Class A clean area, the laminar flow hood is one of the most commonly used purification equipment according to the above conditions. The clean indoor air in the laminar flow hood is filtered by a fan through a high-efficiency filter and blown out from the air outlet surface to form a clean vertical unidirectional flow. The clean airflow flows through the working area at a uniform cross-sectional wind speed, thereby removing the air in the clean area. The dust is taken away, forming a class A cleanliness environment. Take the pneumonia vaccine workshop of a vaccine listed company as an example. Laminar flow hoods are used in the centrifuge room, ultrafiltration room, precipitation room, and extraction and precipitation room.

Application of air purification equipment in the biopharmaceutical industry

In the biopharmaceutical plant, when materials need to be transferred between different clean areas (such as B clean area to A clean area, or D clean area to B clean area), the use of transfer windows can effectively reduce the opening of the clean room. The number of times, the pollution degree of the clean area is reduced to a minimum. When materials enter a high-level clean room from a low-level clean room, the transfer window acts as an airlock from it, preventing unpurified air from entering the clean area and avoiding indoor cleanliness from being affected.

In the pharmaceutical industry, the weighing hood is a special purification equipment used for weighing and dispensing small batches of medicines. It mainly includes a negative pressure weighing hood and an activated carbon weighing hood. The negative pressure weighing hood is mainly used for local purification equipment dedicated to pharmaceuticals, microbiological research and scientific experiments, and the activated carbon weighing hood is mainly used for local purification equipment dedicated to active carbon weighing in the water needle workshop. The weighing hood can provide a vertical one-way airflow. Part of the clean air is circulated in the work area and part is discharged to the nearby area, so that the work area generates negative pressure and prevents cross-contamination. The weighing cover generally adopts a negative pressure design, which can effectively control the spillage and rise of dust, prevent the dust from inhaling the human body, and protect the environment and the safety of personnel in the work area.

For the exhaust system, the bio-pharmaceutical factory usually has an exhaust box and a return air outlet at the end of the clean room, but the toxic and harmful gas discharge should be set separately to ensure that the exhaust section must include a high-efficiency filter (H13/14 efficiency). More and more experts recommend using BIBO as an exhaust filter unit in the exhaust system of vaccine factories and some export pharmaceutical factories (as shown in Figure 3). BIBO is the abbreviation of bag-in-and-bag-out filter unit. It was originally used in the nuclear industry, and then widely used in biosafety laboratories (P3 and P4 levels), and gradually promoted to the biopharmaceutical industry. BIBO is used to remove dangerous pathogenic microbial aerosols in the exhaust. The filter is replaced by a special polymer polyester film bag to completely and safely control high-risk, infectious bacteria and virus microorganisms in the BIBO box. The BIBO used in a new project of a vaccine workshop is composed of a biosafety closed valve, a medium-efficiency filter section, a high-efficiency filter section, and a PAO scanning section, which can meet the OEB level 4 protection requirements.

Application of air purification equipment in the biopharmaceutical industry

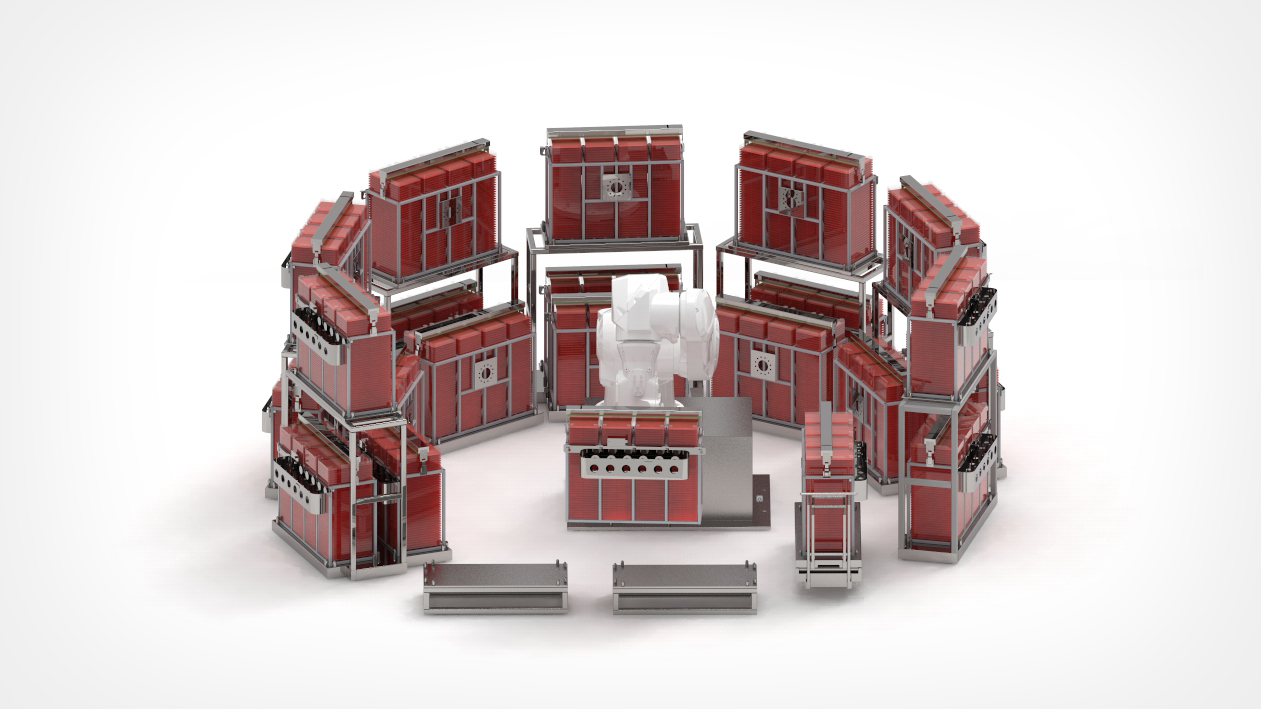

In the pharmaceutical production process, in order to fully ensure the aseptic production level, the isolation system (RABS) is widely used. The limited isolation system can provide a level of aseptic quality close to that of an isolator. RABS provides protection through aerodynamic shielding in critical process areas, allowing operators to open some interventions to achieve the ideal high-level aseptic process. The isolator is a special device in the pharmaceutical production process with occupational exposure risk, providing a closed environment and different measurable pressures between the operators. In principle, the production process can only be intervened through isolation gloves, which is easy to repeat. The process operation is sterilized by the control system each time, and the process can be supported by data.

The ventilation and filtration system of general biopharmaceutical companies can meet their needs by air supply, laminar flow hood, transfer window, weighing hood, and air return. In some specific drug manufacturing links, BIBO, RABS, and isolators can be used as purification equipment. As a professional manufacturer of air purification equipment, MayAir not only provides standard products, but also provides customized solutions for biopharmaceutical customers to meet their needs. MayAir is committed to improving the production environment and medical and health environment of biopharmaceutical companies. Its technical team adopts CFD airflow simulation technology and standardized test and experimental methods, designs and follows technical requirements, installs and provides training services, cooperates with testing and acceptance, and fully meets customer needs. Assist pharmaceutical companies to establish a scientific, GMP-compliant sterile drug production environment and process.